Those who fail to plan...

I’ve found that the old adage of “Those who fail to plan, plan to fail”, is easily modified to state:

As a Quality Management System (QMS) auditor and consultant, I’ve visited many companies during my career… including several Fortune 500 companies. And I've observed that MANY of the nonconformities identified, whether internally or from external QMS auditors, have similar root causes. This is so common that some “Corrective Action” software databases include a selection of “typical” root causes in a “Drop-Down List” - presumably in a misguided effort to assist management in creating Pareto charts to identify the “significant few” from the “trivial many” root causes.

When Root Cause Analysis (RCA) is reduced to simply identifying the proper “Drop-Down List” selection, it becomes obvious that the difference between “common cause variation” and “special cause variation” is not understood. This indicates a fundamentally flawed QMS!

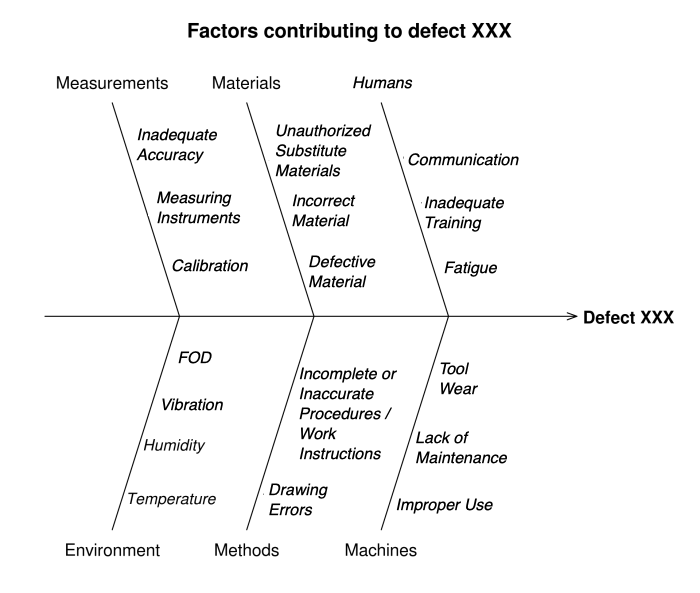

One of the best and most effective tools for performing a structured RCA is the Ishikawa Fishbone chart (shown below). Fishbone charts typically categorize problems through the 6 Ms (Manpower, Materials, Measurements, Machines, Methods & Mother Nature) that originated with Lean Manufacturing and the Toyota Production System.

And Fishbone charts are commonly used as a structured approach to identifying “Failure Modes” in a FMEA (Failure Mode and Effects Analysis).

Had a series of PFMEAs (Process Failure Mode and Effects Analysis) been completed during the planning stage, virtually all of the “root causes” (special cause variations) would have been eliminated before they were realized. And where issues are identified that contribute to process “common cause variation” (that can only be eliminated through changing the process), the PFMEA will be helpful in identifying actions to “mitigate” the likelihood of occurrence and/or the severity of its impact.

Very few of the companies I've visited have ever performed any PFMEAs as part of their planning. IF they had, then the costs associated with their product returns, customer complaints, and performing individual Root Cause Analysis (RCAs) and Corrective Actions would have been dramatically reduced. This is especially true when “common cause” variations have been misidentified as “special cause” variations… leading to completely ineffective corrective actions.

Below are some common examples of “Failure Modes” categorized within the 6 Ms:

| Category | Failure Mode |

|---|---|

| Personnel | Training Content (e.g., incomplete, confusing/cryptic, obsolete) |

| Training not updated to stay aligned with process changes (e.g., new equipment) | |

| Instructor Knowledge / Competence (Lack of a “Train the Trainer” program) | |

| Trainee Comprehension / Understanding (Lack of, or inadequate testing) | |

| Trainee Competence (Ineffective demonstration of competence) | |

| Requirements not communicated (due to ineffective communication between functions & Personnel) | |

| Materials | Incorrect material received - due to incorrect specifications communicated to the supplier |

| Incorrect material received - due to inadequate control of changes to orders | |

| Incorrect material received - due to unauthorised substitution | |

| Nonconforming material received - due to inadequate material acceptance inspection requirements | |

| Nonconforming material received - due to no acceptance inspection/verification performed on material | |

| Nonconforming material - due to incorrect, incomplete, or missing identification | |

| Nonconforming material - due to improper handling packaging (damage) | |

| Nonconforming material - due to improper storage of materials (damage or spoilage) | |

| Nonconforming material - due to Material shelf life exceeded | |

| Measurements | Tolerances not clearly specified |

| Tolerances are specified, but not achievable with existing equipment | |

| Inadequate performance measurement and assessment | |

| Process Capability is unknown | |

| Equipment | Improper or Inadequate Measuring and/or Test Equipment (e.g., lacking accuracy, past its calibration due date) |

| Equipment not under a Preventive Maintenance Program | |

| Methods | No documented procedures/work instructions exists for process |

| Procedures/work instructions not readily available to personnel | |

| Procedures/work instructions do not include clear revision levels (to determine the applicable version) | |

| Inadequate recall/removals of obsolete procedures/work instructions | |

| Environment | Lighting (e.g., Lack of defined requirements for illumination) |

| Temperature and/or humidity requirements not defined for material(s) and/or process(es) | |

| Temperature and/or humidity requirements exceeded but not being monitored or reported | |

| Foreign Object Debris / Damage (FOD) |

So why isn't your company performing PFMEAs… or equivalent risk assessments?