Table of Contents

NIST Traceability Numbers - The Sasquatch of Metrology

Every so often, I'll hear of an experienced Quality Management System (QMS) Auditor insisting that the only way to prove calibration (metrological) traceability is through the inclusion of NIST Traceability/Test numbers on a calibration certificate.

Every so often, I'll hear of an experienced Quality Management System (QMS) Auditor insisting that the only way to prove calibration (metrological) traceability is through the inclusion of NIST Traceability/Test numbers on a calibration certificate.

Actually, there is no such thing as a NIST “traceability” number. And the NIST “Test Number” is for administrative purposes only. This is supported by official interpretations from NIST.

NIST GMP 13, "Good Measurement Practice

for Ensuring Metrological Traceability”, sec. 1.1 (3rd para.):

“Test numbers issued by NIST should not be used nor required as proof of the adequacy or traceability of a test or measurement. Having a NIST number does not provide evidence that the measurement value provided by another organization has the property of metrological traceability.”

And

NIST GMP 13, "Good Measurement Practice

for Ensuring Metrological Traceability”, sec. 1.6.3, “Use of, or reference to, official test numbers of a national metrology institute.”:

“Having an authentic test number does not provide assurance or evidence that the measurement value provided by another organization is traceable. Not only must there be an unbroken chain of comparisons, but each measurement must be accompanied by a statement of uncertainty associated with the value. Test report numbers should not be used nor required as proof of the adequacy or traceability of a test or measurement. National and international documentary standards for test and measurement quality requirements, such as ISO 10012, ISO/IEC 17025 and the ISO 9000 series, provide guidance for assessing metrological traceability and do not require the use or reporting of specific test numbers to establish metrological traceability.”

This is further noted in the:

NIST "Supplementary Materials for NIST Policy Review”:

I.B.4 Is a NIST Test Report Number necessary and/or sufficient evidence of traceability?

“Test report numbers issued by NIST are intended to be used solely for administrative purposes. Although they are often used to uniquely identify documents which bear evidence of traceability, test report numbers themselves do not address the issues listed in I.B.1 above, and should not be used nor required as the sole proof of traceability.”

What "exactly" is metrological traceability?

Metrological Traceability

property of a measurement result whereby the result can be related to a reference through a documented unbroken chain of calibrations, each contributing to the measurement uncertainty.

Source: The "Bureau International des Poids et Mesures" (BIPM) JCGM 200:2012, "International vocabulary of metrology – Basic and general concepts and associated terms (VIM)" (3rd edition), sec. 2.41 (which is freely available), This document is also published as ISO/IEC Guide 99, “International vocabulary of metrology – Basic and general concepts and associated terms (VIM)”

An "unbroken chain of calibrations" to what?

Both ISO 9001:2015 & AS9100:2016 (Rev. D) state:

ISO 9001:2015 & AS9100:2016, sec. 7.1.5.2 Measurement Traceability

“When measurement traceability is a requirement, or is considered by the organization to be an essential part of providing confidence in the validity of measurement results, measuring equipment shall be:

a. calibrated or verified, or both, at specified intervals, or prior to use, against measurement standards traceable to international or national measurement standards; when no such standards exist, the basis used for calibration or verification shall be retained as documented information;”

Unfortunately, the language in ISO 9001:2015 & AS9100:2016 (Rev. D) is extremely antiquated in stating its requirements for “measurement traceability”. And, unfortunately, similar antiquated language appears in U.S. Regulations. For example, 21 CFR 820.72 states:

TITLE 21–FOOD AND DRUGS

CHAPTER I–FOOD AND DRUG ADMINISTRATION

DEPARTMENT OF HEALTH AND HUMAN SERVICES

SUBCHAPTER H–MEDICAL DEVICES

PART 820 – QUALITY SYSTEM REGULATION

Subpart G–Production and Process Controls

Sec. 820.72 Inspection, measuring, and test equipment.

(b) (1) Calibration standards. Calibration standards used for inspection, measuring, and test equipment shall be traceable to national or international standards. If national or international standards are not practical or available, the manufacturer shall use an independent reproducible standard. If no applicable standard exists, the manufacturer shall establish and maintain an in-house standard.

Similar antiquated language appears in MIL-STD-1309D, (12 February 1992), which doesn't even recognize international standards or offer alternatives where no national measurement standards exist:

MIL-STD-1309D, “Definitions of Terms for Testing, Measurement and Diagnostics”

3.1.653 Traceability. The ability to relate individual measurement results to national standards or nationally accepted measurement systems through an unbroken chain of comparisons.

In contrast, ISO 17025:2017 is much more modern and technically correct in stating:

ISO 17025:2017, “General requirements for the competence of testing and calibration laboratories”

6.5.2 The laboratory shall ensure that measurement results are traceable to the International System of Units (SI) through:

a) calibration provided by a competent laboratory; or

NOTE 1 Laboratories fulfilling the requirements of this document are considered to be competent.

b) certified values of certified reference materials provided by a competent producer with stated metrological traceability to the SI; or

NOTE 2 Reference material producers fulfilling the requirements of ISO 17034 are considered to be competent.

c) direct realization of the SI units ensured by comparison, directly or indirectly, with national or international standards.

NOTE 3 Details of practical realization of the definitions of some important units are given in the SI brochure.

So, what we're actually seeking is metrological traceability to SI units.

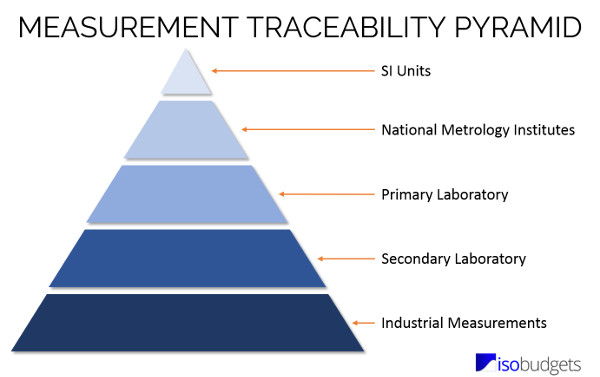

The below graphic (from the article "Measurement Traceability: Complying with ISO 17025 Requirements" - By Richard Hogan) provides an excellent depiction of the “typical” metrological hierarchy to SI units.

I describe the above pyramid as “typical” because, contrary to the antiquated language of ISO 9001:2015 & AS9100:2016, it is possible to “bypass” the National Metrology Institutes (NMIs) to obtain traceability directly to SI units. Using the example of DC volts, Fluke, a world leader in the field of metrology, owns a Josephson voltage system, which they can use to realize the SI Units directly.

Also, while not strictly speaking a National Metrology Institute (NMI), the "Bureau International des Poids et Mesures" (BIPM) offers calibration & Measurement services (with traceability to SI Units) to its Member States. In that instance, the BIPM would serve as equivalent to a NMI.

Transcat has an excellent White Paper on this topic at: https://www.transcat.com/calibration-resources/white-papers/what-is-measurement-traceability.

What are SI Units?

Adopted by the General Conference on Weights and Measures (CGPM) in 1960, the “International System of Units” (Système International d'Unités, with the international abbreviation SI) consists of 7 base units that define 22 derived units. The base SI units are all derived from intrinsic (i.e., invariant) constants of nature, such as the speed of light in vacuum and the Boltzmann constant (which serves as the basis for the Kelvin temperature scale). According to Dr. Chris Sutton, “the SI system of units allows for complete coverage of all scientific measurements”.

Adopted by the General Conference on Weights and Measures (CGPM) in 1960, the “International System of Units” (Système International d'Unités, with the international abbreviation SI) consists of 7 base units that define 22 derived units. The base SI units are all derived from intrinsic (i.e., invariant) constants of nature, such as the speed of light in vacuum and the Boltzmann constant (which serves as the basis for the Kelvin temperature scale). According to Dr. Chris Sutton, “the SI system of units allows for complete coverage of all scientific measurements”.

The SI Units are defined in the SI Brochure, which is published by the “Bureau International des Poids et Mesures” (BIPM), located in France.

Because SI units are derived from intrinsic (i.e., invariant) constants of nature, “intrinsic measurement standards” exist. This is acknowledged in ISO 17025:2017, sec. 6.5.2, which provides 3 (three) different methodologies for achieving metrological traceability. And is further clarified in ISO 17025:2017, “Annex A: Metrological traceability”.

ISO 17025:2017, “Annex A: Metrological traceability”

A.2 Establishing metrological traceability

A.2.1 Metrological traceability is established by considering, and then ensuring, the following:

b) a documented unbroken chain of calibrations going back to stated and appropriate references (appropriate references include national or international standards, and intrinsic standards);

SI Units are also explained on the NIST web site at: https://www.nist.gov/pml/weights-and-measures/metric-si/si-units and in “NIST Special Publication 330 - The International System of Units (SI)”.

What are "intrinsic" standards?

Intrinsic Measurement Standard

measurement standard based on an inherent and reproducible property of a phenomenon or substance.

EXAMPLE 1 Triple‑point‑of‑water cell as an intrinsic measurement standard of thermodynamic temperature.

EXAMPLE 2 Intrinsic measurement standard of electric potential difference based on the Josephson effect.

EXAMPLE 3 Intrinsic measurement standard of electric resistance based on the quantum Hall effect.

EXAMPLE 4 Sample of copper as an intrinsic measurement standard of electric conductivity.

NOTE 1 A quantity value of an intrinsic measurement standard is assigned by consensus and does not need to be established by relating it to another measurement standard of the same type. Its measurement uncertainty is determined by considering two components: the first associated with its consensus quantity value and the second associated with its construction, implementation, and maintenance.

NOTE 2 An intrinsic measurement standard usually consists of a system produced according to the requirements of a consensus procedure and subject to periodic verification. The consensus procedure may contain provisions for the application of corrections necessitated by the implementation.

NOTE 3 Intrinsic measurement standards that are based on quantum phenomena usually have outstanding stability.

NOTE 4 The adjective “intrinsic” does not mean that such a measurement standard may be implemented and used without special care or that such a measurement standard is immune to internal and external influences.

Source: The “Bureau International des Poids et Mesures” (BIPM) JCGM 200:2012, "International vocabulary of metrology – Basic and general concepts and associated terms (VIM)" (3rd edition), sec. 5.10.

As mentioned earlier, Fluke owns a Josephson voltage system, which they can use to realize the SI Units directly for DC Volts. Even though they don't send an instrument to NIST for calibration, they compare their Josephson voltage system to an identical Josephson Voltage system maintained by NIST.

Legal Metrology

Fluke performs this comparison described above because, just as the requirements for “measurement traceability” contained in ISO 9001:2015 & AS9100:2016 (Rev. D) are antiquated, so is U.S. law in this area. U.S. Law has designated NIST as holding the national standards of measurement, and NIST has defined the U.S. legal volt to be produced from its one particular Josephson voltage system, so it is the national standard. However, this is only pertinent to the area of “legal metrology” (Ref.: International Organization of Legal Metrology).

What are "International Standards"?

While ISO 9001:2015, AS9100:2016 (Rev. D) and ISO 17025:2017 all mention “International Standards”, none of them define what this means. Fortunately, the “Bureau International des Poids et Mesures” (BIPM) JCGM 200:2012, "International vocabulary of metrology – Basic and general concepts and associated terms (VIM)" (3rd edition), defines this term.

International Measurement Standard

measurement standard recognized by signatories to an international agreement and intended to serve worldwide

EXAMPLE 1 The international prototype of the kilogram.

EXAMPLE 2 Chorionic Gonadotrophin, World Health Organization (WHO) 4th international standard 1999, 75/589, 650 International Units per ampoule.

EXAMPLE 3 VSMOW2 (Vienna Standard Mean Ocean Water) distributed by the International Atomic Energy Agency (IAEA) for differential stable isotope amount-of- substance ratio measurements.

Source: The “Bureau International des Poids et Mesures” (BIPM) JCGM 200:2012, "International vocabulary of metrology – Basic and general concepts and associated terms (VIM)" (3rd edition), sec. 5.2.

I am aware of only four (4) “international standards” (as opposed to SI units); three of which are listed as examples in the definition shown above. However, there are probably others. Those that I am aware of include:

1 - The international prototype of the kilogram (OBSOLETE as of May 20, 2019)

All of the SI units are based on physical constants of nature EXCEPT the kilogram. The kilogram is the unit of mass; which nominally has the same mass as one litre of water at the freezing point.

The only SI unit “physical artifact” (i.e., not defined by a fundamental, natural constant), the international prototype kilogram (IPK), was certified in 1889, and consists of a cylinder of platinum-iridium. The IPK is maintained by the BIPM.

Because the IPKs stability has been a matter of significant concern, during November 2018, the world’s measurement experts voted and unanimously approved a revision of the SI that establishes a measurement system entirely based on physical constants of nature. The changes took effect on World Metrology Day, May 20, 2019; which commemorates the anniversary of the signing of the Metre Convention in 1875. See The Kilogram is Dead; Long Live the Kilogram

2 - Chorionic Gonadotrophin (Biological standard)

Defined by the World Health Organization (WHO) in the 4th international standard 1999, as 75/589, 650 International Units per ampoule.

3 & 4 - VSMOW2 (Vienna Standard Mean Ocean Water) & SLAP2 (Standard Light Antarctic Precipitation)

Distributed by the "International Atomic Energy Agency" (IAEA) for differential stable isotope amount-of-substance ratio measurements, the VSMOW2 & SLAP2 reference material standards are used in producing the triple point of water (see the BIPM “Guide to the Realization of the ITS-90 - Triple Point of Water”) with the smallest amount of uncertainty.

Traceability to Organizations, rather than SI Units

The US Federal Aviation Administration, “FAA National Policy - Order 6200.4G” (dated 03/08/10) states:

FAA National Policy - Order 6200.4G

Appendix 2 - Definitions

h. Calibration Standard - a device or instrument used as a basis to calibrate measure, gage, test, inspect, or otherwise examine basic accuracy values. The standard has a higher order of accuracy than the examined item and is traceable to the National Institute of Standards and Technology (NIST).

Specifying that a calibration service provider must supply “NIST Traceable” calibration certifications, which this policy essentially requires, not only reveals a lack of understanding “metrological traceability”, it ignores the reality that many calibrations, whether from NMIs (e.g., the NRC in Canada, CENAM in Mexico, PTB in Germany,) or accredited commercial metrology laboratories, may be traceable to SI units through other means (e.g., intrinsic measurement standards).

This is politely pointed out by the ILAC – International Laboratory Accreditation Cooperation".

ILAC-P10:01/2013, “Preamble” (2nd paragraph)

The persistent misconception that metrological traceability may be linked to a particular organization (e.g., “traceable to a specific National Metrology Institute”) fosters continued confusion with regard to its nature. Metrological traceability pertains to reference quantity values of measurement standards and results, not the organization providing the results.

Source: ILAC-P10:01/2013, "ILAC Policy on the Traceability of Measurement Results"“

Conclusion

Unless required by statute or regulation (i.e., for Legal Metrology), mandating “NIST traceability” unnecessarily “limits” the sources for metrological traceability, excluding other NMIs and/or accredited commercial metrology laboratories.

NIST, for example, is a non-regulatory agency of the United States Department of Commerce. When the US Government was “shut down” during 1995, 2013, 2018, and 2019, NIST operations were suspended. So if your company had measurement standards at NIST awaiting calibration, or if you outsourced calibration to a metrology lab who had its measurement standards at NIST, then the length of time associated with the government “shutdown” was added to the delay in receiving those instruments. These government “shutdowns” create a “ripple effect” throughout industry.

To avoid this, standards writing bodies and regulatory agencies should gain a better understanding of “metrological traceability” and allow other NMIs and/or accredited commercial metrology laboratories to be utilized in providing metrological traceability to SI units. In particular, these bodies should promote international consistency of measurements through adopting the recommendations of the "Joint BIPM, OIML, ISO and ILAC Declaration on Metrological Traceability".

For more information visit: https://us.flukecal.com/literature/about-calibration